How it works

Our technology works through a precise, scientifically designed and field-proven process.

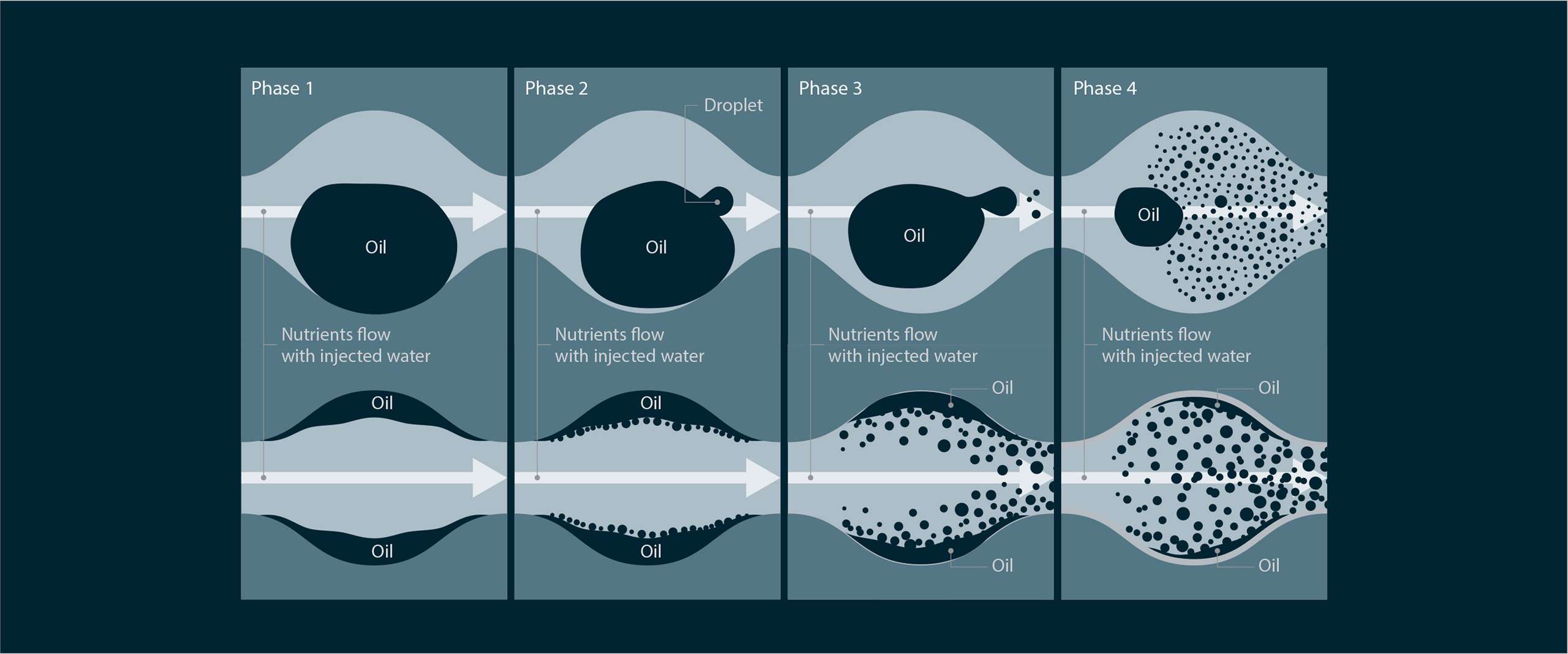

Our four-step process

From field screening to full-field scale within 6 months

Step 1 - Field screening of reservoir characteristics

Reservoirs are analysed by reviewing technical and environmental characteristics to ensure they are suitable candidates for Organic Oil Recovery.

Step 2 - Ecology validation

Production water samples are collected from target producer wells using a provided sampling kit and sent for comprehensive laboratory analysis. This includes growth studies under reservoir conditions and DNA/RNA profiling to assess the native microbial community. By testing actual in-situ microbes at reservoir specific conditions, the analysis confirms whether the OOR process is compatible with the reservoir, evaluating mechanistic changes and the quality of microbial response.

Microbes native to oil reservoirs are challenging to cultivate outside of their native habitat, a successful lab response strongly indicates that the process will perform well in the field. Upon completion, results are relayed, and if favorable, a recommendation is made to proceed.

Step 3 - In-situ reservoir validation

This is an In‑situ Microbial Response Test, designed to confirm that the nutrient formula developed in the lab performs in the field as expected. The test can be conducted via inter-well treatments or producer huff‑n‑puff applications. Following injection, microbial and economic responses are monitored to guide progress to the next stage.

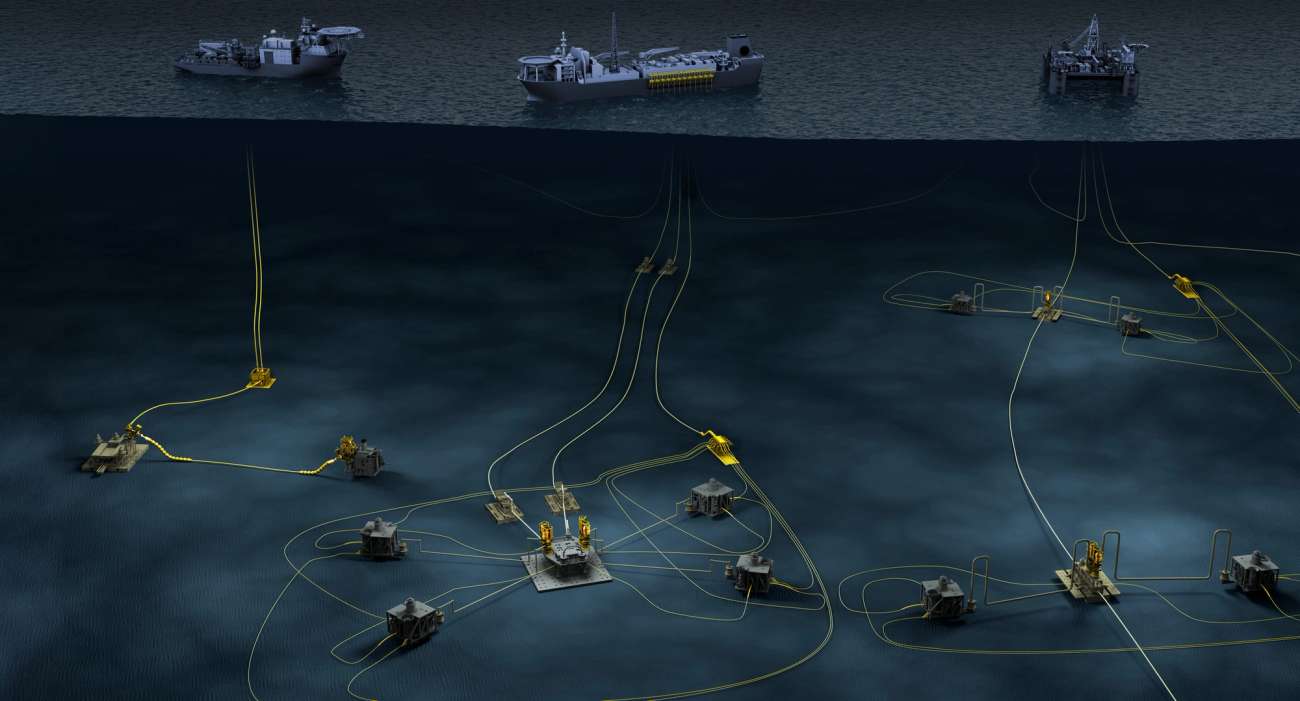

Step 4 - Full-field expansion

Scale to full-field to maximise economic recovery as effectively as possible. Always batch treatments. Always zero-capex.

Optimising reservoir performance and recovery rates

Explore the evidence

Case studies and technical research supporting OOR.

Start the conversation with our experts today